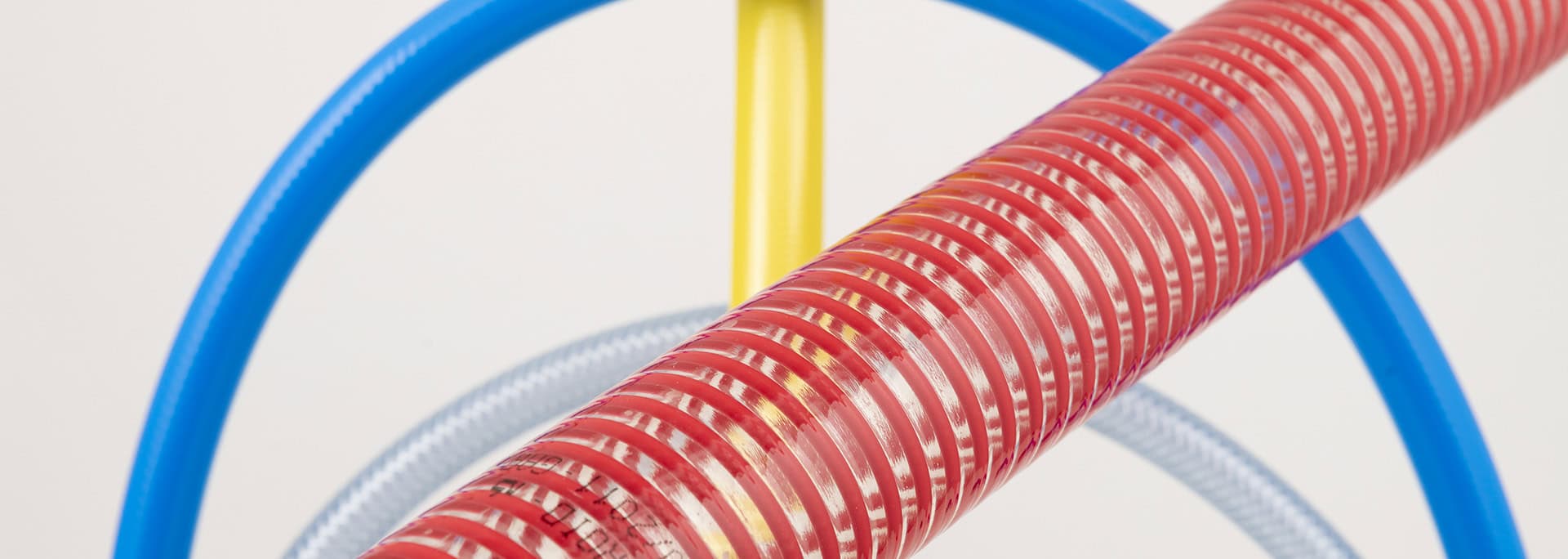

Join us in Hall 11 – H46 to explore how our modular dosing technology transforms plastics manufacturing—helping companies improve efficiency, reduce waste, and enhance product quality. Whether you’re looking for solutions in gravimetric dosing, regrind processing, or automation, our team is ready to help you take dosing in your production to the next level.

Movacolor at K 2025

Movacolor’s Latest Innovations

MDS Balance Drydose

Labotek and Movacolor have joined forces and developed an innovative solution to address the need for drying additives. The result is the MDS Balance Drydose. This new system is a one-of-a-kind system that combines efficient material drying and precise additive dosing in a single, compact unit.

The Drydose accommodates the upward trend of drying additives due to increasing quality requirements, materials of biological origin, specialty engineered plastics, and the need to further reduce quality risks.

By drying materials directly within the dosing unit at the machine inlet, the Drydose ensures optimal moisture control and removes the need for additional drying equipment. This integrated approach enhances product consistency, reduces waste and energy consumption, and improves overall production efficiency.

VoluTouch VTCM and percentage setting

Movacolor is now expanding its VoluTouch controller range with a metal (VTCM) version targeted for environments in which mechanical robustness is key. The MDS Volumetric Feeder is controlled from the same user friendly and intuitive touchscreen. The touchscreen control is expanded with a percentage setting wizard and percentage control for increased operator efficiency.

MovaLink integrated control

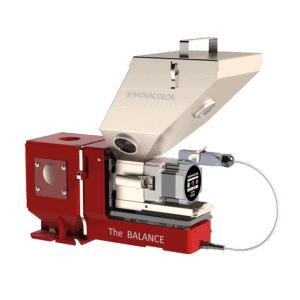

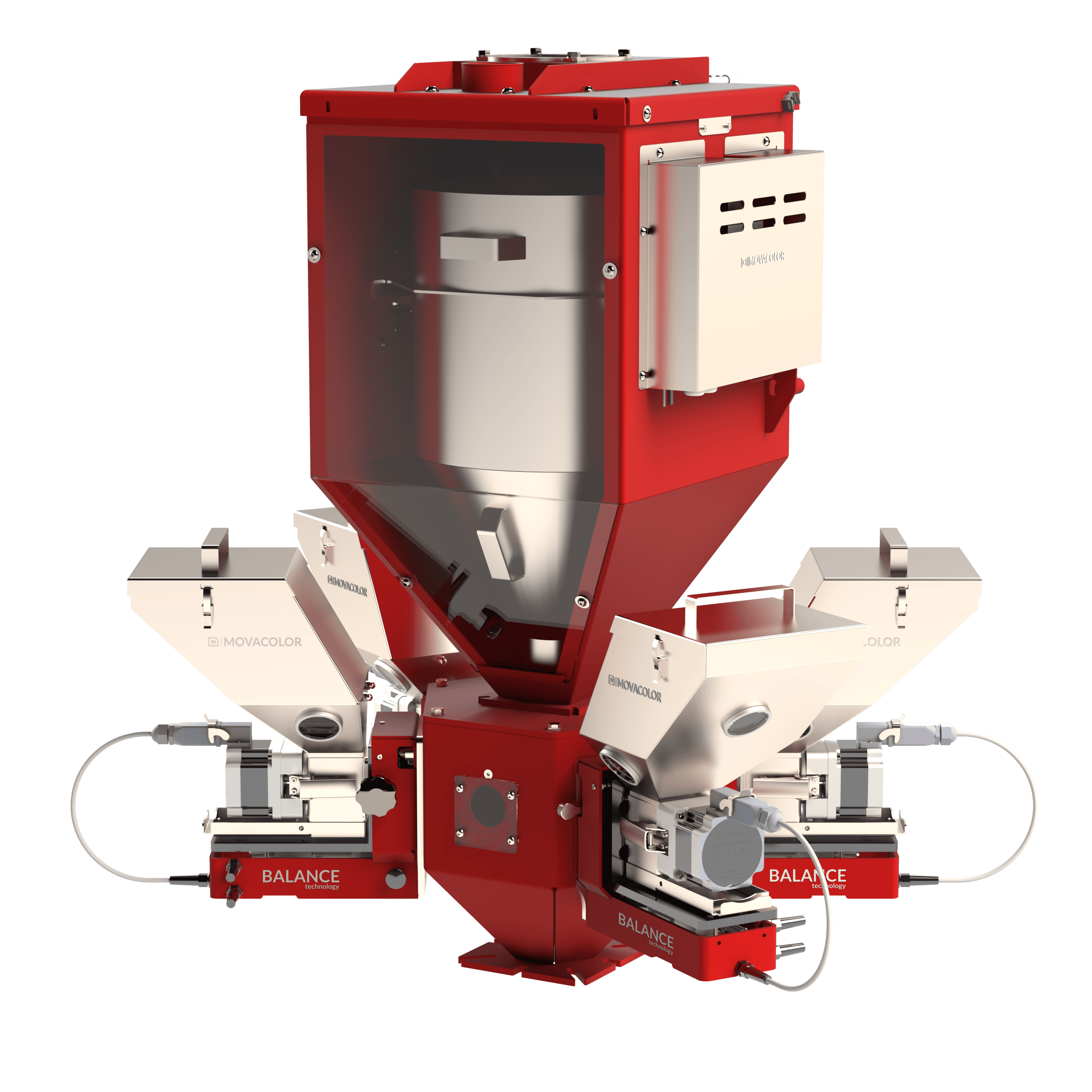

Why Choose the MDS Balance?

The MDS Balance sets a new standard in precision dosing, offering a smarter alternative to traditional volumetric feeders. Unlike conventional systems, it operates on a loss-in-weight principle, meaning it constantly measures and adjusts material flow in real time. This ensures stable dosing, even when external factors like material density fluctuations or environmental changes come into play.

More than just a dosing solution, the MDS Balance is also the better alternative to blending when accuracy and consistency matter most. It eliminates the risks of unmixing and low shot-to-shot accuracy, which are common issues in blending processes. By delivering precise, reliable dosing directly at the feed throat, the MDS Balance enhances product quality, reduces material waste, and ensures unmatched control over your production.

“After installing the MDS Balance Drydose, our previous streaking problems when adding additives are simply gone!” Bernd Wilming, Plant Manager, agathon GmbH

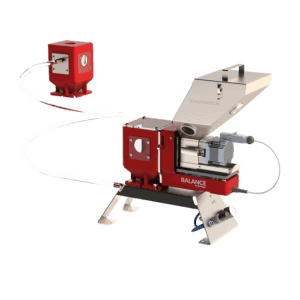

MCS Continuous Feeder

Our renowned MDS Balance helps manufacturers accurately dose additives with 0.5% accuracy. However, it is important for some clients to get additional control by adding an MMS Weight to measure the main material flow in both throughput and kg/h. This new configuration provides additional control and insight and allows:

- Operators to dynamically adjust dosing rates according to main material consumption.

- Measurability for a wide variety of additives, including regrind, powder, and masterbatch.

- Several departments to measure total main material consumption.

- Automation of the order process for main materials as well as additives.

- Full traceability of all materials in production.

By combining the MMS Weight with our MDS Balance, the MCS Continuous Feeder can measure both main material and additives, resulting in the most cost-effective dosing accuracy possible in your production. The technology behind measuring your main material ensures that your gravimetric dosing units automatically adjust the feed rate to bulk density changes, material consumption, and capacity variation of the extruder.

Learn more about the products we are showcasing at K 2025

Click on any of the products below to explore them. Alternatively, keep scrolling to learn more about our MDS Balance and the industry trends to look out for at K 2025

MDS Balance Drydose

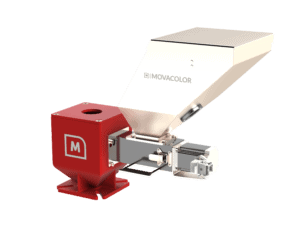

MDS Balance

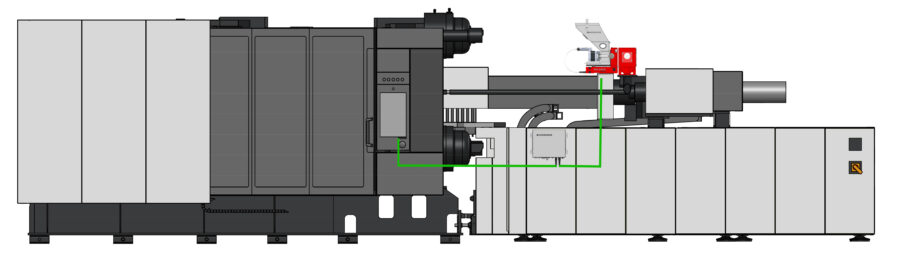

MCS Off-line dosing

A configured solution for increasing factory safety by placing the MDS Balance on the ground floor, next to the production machine.

Products we’re also taking:

We invite all attendees to visit our booth to explore how our advanced dosing solutions can drive your business toward a more sustainable future.

Don’t miss out on the opportunity to see us in Düsseldorf—come and discover what Movacolor offers at K 2025