Optometric dosing, first introduced by Movacolor in the year 2016, is a state-of-the-art method for accurately measuring and dispensing plastic materials using laser technology. This technique finds common use in highly precise plastic manufacturing applications like healthcare and automotive. Optometric dosing involves a dosing disk and a optical sensor to count plastic pellets individually, ensuring a remarkable accuracy rate of 100% and providing complete control over the dosing process.

How does Optometric Dosing work?

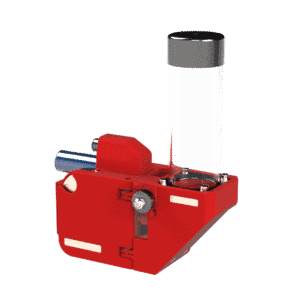

The optometric dosing technology is unique in the world of dosing. But how does it work? An air cartridge creates a vacuum behind a disc with small holes. The disc spins and picks up the pellets of masterbatch. An optometric sensor detects the masterbatch pellets when the sensor signal is being blocked. With this technique our software is able to count the pieces of masterbatch pellet by pellet. If the small air cartridge misses one pellet of masterbatch or more, the sensor of the optometric dosing system will notice and the dosing disc will correct the missing pellets by spinning a bit faster.

Optometric Dosing Systems for Small High-precision End Products

The optometric dosing technology has been developed for manufacturers producing high-precision end products on micro-injection machines and/or micro-extruders. Even with shot weights of less than 1 gram, this technology remains effective. Because these type of injection molding machines and extruders have limited mixing capabilities, and the end products require very precise tolerances, pre-compounded material is usually used for these applications. However, producing these specialized pre-compounded materials is quite expensive due to the small production quantities. To address this issue, our engineers came up with the optometric dosing technology. These extremely precise dosing systems offer the advantage of significant cost reduction by enabling the use of standard virgin material in combination with masterbatch or additive dosing.

Our adaptable dosing approach empowers you to personalize your configuration and/or merge multiple units, guaranteeing a dosing system that perfectly aligns with your production needs. Should you encounter difficulties in discovering the optimal solution for your manufacturing process, kindly share your contact information in the provided form below. Our team of dosing experts is ready to provide you with free advice!