Are you looking for a gravimetric feeder that allows you not only to dispense additives accurately, but also to measure the total additive consumption of your production process?

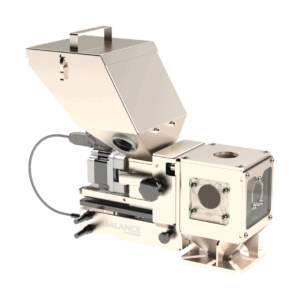

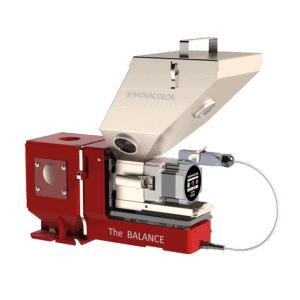

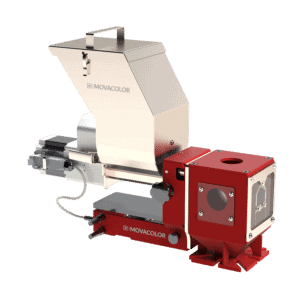

At Movacolor, we offer a wide range of gravimetric feeders, whether you are dealing with powders, liquids, or granular material. Explore our MDS Balance, a gravimetric feeder with over 30 years of active development, capable of dispensing material with an accuracy up to 0.05%.

What to consider when purchasing a gravimetric feeder?

Gravimetric dosing is a method used in various fields, particularly in the plastics industry, to accurately measure and dispense materials based on their weight.

Gravimetric dosing involves measuring a substance’s weight mass and using loss-in-weight technology to control the material dispersion. It offers a high level of precision and control compared to for example volumetric dosing methods, which rely solely on measuring volume.

In gravimetric dosing, the process typically involves the following steps:

- Weighing – The substance to be dosed is placed on a precision scale, and its mass is measured with a high degree of accuracy. This measurement can be carried out using various types of weighing equipment, such as load cells.

- Dispensing – Based on the desired dosage and the measured weight of the substance, the dosing system dispenses the required amount of material by using augers and dosing cylinders.

- Feedback Control – Throughout the dosing process, a control system continuously monitors the weight of the material being dispensed. If there are any deviations from the desired dosage, the control system automatically adjusts the dosing rate to maintain accuracy.

Gravimetric dosing offers several advantages to your production:

- Accuracy – Since it relies on actual mass measurements, gravimetric dosing is highly accurate and is less affected by variations in material density, temperature, or other factors that can influence volume-based measurements.

- Flexibility – Gravimetric dosing can be used for a wide range of materials, from powders and granules to liquids, as long as they can be reliably weighed.

- Consistency – The precise control provided by gravimetric dosing ensures that each dose is consistent, which is crucial in industries where product quality and uniformity are essential.

- Process Optimization – Gravimetric dosing systems can be integrated into automated production lines, allowing for efficient and optimized manufacturing processes, with the least amount of downtime as possible.

- Reduced Waste – Accurate dosing reduces material waste and contributes to cost savings.

Limit Waste, Reduce Costs, and Increase Product Quality with Gravimetric Dosing and Blending Solutions from Movacolor

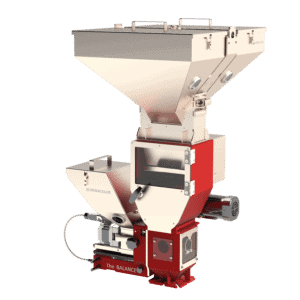

Over the years, we have developed a wide range of high-precision modular gravimetric dosing and blending systems for plastic producers worldwide, catering to any application. Whether you’re looking for a loss-in-weight feeder or a gravimetric batch blender, we’ve got you covered. Our gravimetric solutions are designed to offer you complete control and are easily adaptable to any process, whether it’s extrusion, injection molding, or blow molding. By opting for a gravimetric dosing solution from Movacolor, you can reduce costs, reduce waste, and maximize production efficiency.

Our gravimetric feeders integrate with our Balance Technology, which measures the loss in weight of your hopper contents. While dispensing, our gravimetric feeders dynamically adjust the feed rate of your dosing cylinder to rule out any deviations caused by vibrations or other production variables. If your gravimetric feeder is experiencing accuracy issues due to vibrations, the MCS Off-line dosing is an excellent alternative to accurately feeding materials in a high-vibration production environment.

Our gravimetric blenders also use loss-in-weight to add material to your production process. However, the gravimetric blender uses a mixing chamber with a rotating valve to mix the materials prior to being fed into your production. Are you looking for a new gravimetric blender that offers the best of both world; dosing and blending? Consider the MHBS Hybrid Blender, a gravimetric blender that combines the MBS Blender with the MDS Balance for inline dosing of your most valuable additives.

Our modular dosing concept allows you to customize your setup and/or combine multiple units, ensuring a dosing system that fits your production requirements. If you’re struggling to find the right solution for your production process please leave your contact details in the form below to get in touch with one of our dosing specialists. We would be happy to provide you with free advice!