Are you looking to dose granular material with consistent flow and accuracy? Color granular dosing with our gravimetric or volumetric dosing solutions results in reliable color, helping you get a high-quality end product. Whether you’re in injection molding, extrusion, or blow molding, our product specialists are committed to finding a suitable color granular dosing unit for your production.

Plastic product producers from all over the world are involved in the development of the highly accurate granular dosing systems of Movacolor. Their experiences with colorants and desire for stable production processes, high efficiency and savings form the starting point for Movacolor’s innovations in dosing technology.

Granular dosing systems with precise control

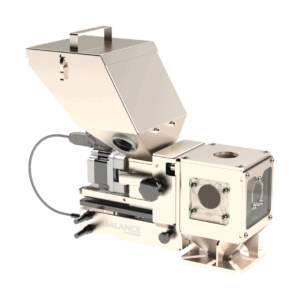

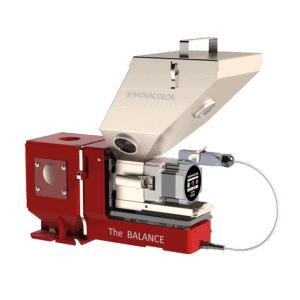

The gravimetric inline color granular dosing system MDS Balance guarantees optimal measurement in the dosing process in extrusion and injection molding applications. The MDS Balance can be upgraded to a multi-component dosing system for dosing up to six additives simultaneously.

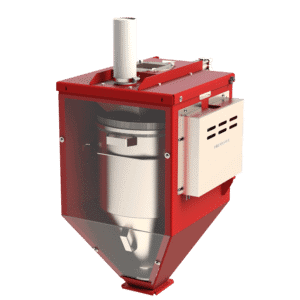

For high-output processes, Movacolor’s engineering department developed the MDS HO Balance. This granular dosing system has a capacity between 50 kg/h and 1,000 kg/h. Of course, with the high level of precision for color granular guaranteed.

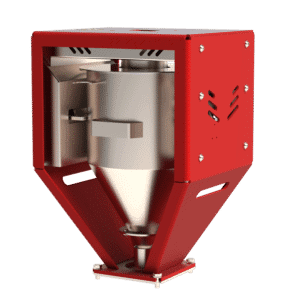

The smallest granular capacity dosed with Movacolor’s inline feeders is no less than 0.1 kg/h. The dosing system that can dose such a small amount is the MDS Nexus.