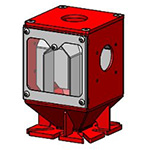

The MDS Nexus is explicitly developed for plastic manufacturers who require exact dosing of extremely low amounts of additives.

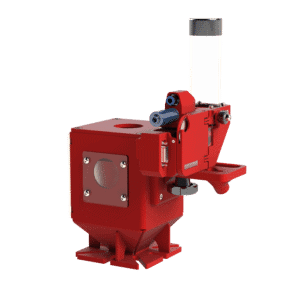

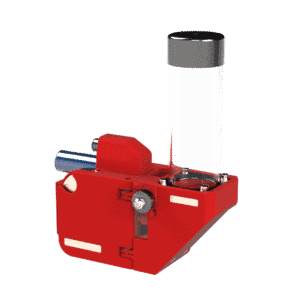

With its specially designed dosing disc and laser technology, this optometric dosing solution counts pellets individually up to 5 pellets per second, resulting in 100% accuracy and complete control over your additive dosing. Remarkably compact at only around 200 mm in length, the MDS Nexus effortlessly integrates into micro injection molding machines and lab extruders. Additionally, its design includes 3D-printed parts, which minimizes the number of components and enhances its overall durability.

The MDS Nexus uses a missed pellet recovery algorithm that ensures continuous and accurate production, even if 4 out of 5 pellets enter the dosing disc. This level of precision and control makes it well-suited and valuable for small plastic parts in ultra-precise applications due to its small shot weights.

Due to its exceptional precision and reliability, the MDS Nexus can significantly improve efficiency and reduce material waste, resulting in substantial savings and enhanced product quality.

Standard Equipment

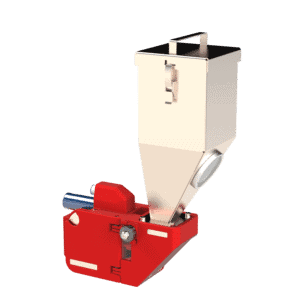

- Three types of dosing discs for handling granules of different sizes

- Transparent 200ml hopper

- 8” full color touch screen controller

- Neckpiece

- Energy saving function

The MDS Nexus is part of our modular dosing concept and can be tailored to suit your production requirements.

Ready to dose plastic material with 100% accuracy? Contact our product specialists today and discover how the MDS Nexus can deliver the highest color accuracy in your production.