IKEA Line

During our visit, we were invited to take a tour around the factory together with Jelle Wibo Elsinga who is one of the process engineers at Enitor Primo. Jelle showed us several production lines and explained what they are producing on each line, the challenges they face, and how our dosing systems help them maintain high quality.

One of the lines shown by Jelle stands out from the rest. The IKEA kitchen plinth line. What is special about this line is that on this line they manufacture a complete product from beginning to end, so from granule to complete consumer-ready product, all behind each other in one multi-step production line. Jelle explained that high-demanding customers like IKEA only want to collaborate with companies that think along with them and ensure a picture-perfect product. Additionally, they also prefer that you take responsibility for the potential waste that comes along with the production process.

“We produce for IKEA, where we make the kitchen plinths, and that is a complete product, so the booklets with instructions are already in there. There we also use Movacolor for adding the right amount of regrind, which is material that has been used before.” Jelle Wibo Elsinga

Therefore, they have chosen to use a dosing solution on this line that automatically adds regrind material to the dosing process based on the throughput of the main material. This configuration enables them to limit waste and save costs on raw materials.

Specialists in Extrusion

The quality of the final product is determined not only by the machine but also by the person operating the machine. During our tour, we got talking to one of the operators responsible for controlling an extrusion line. It quickly became clear that their excellent teamwork and expertise is a cornerstone for the success of their plant. However, their expertise does not come without hard work and failures. That is why they regularly conduct tests together with the R&D department to see if all quality requirements are met and/or if efficiency gains can be made.

Measuring is Knowing

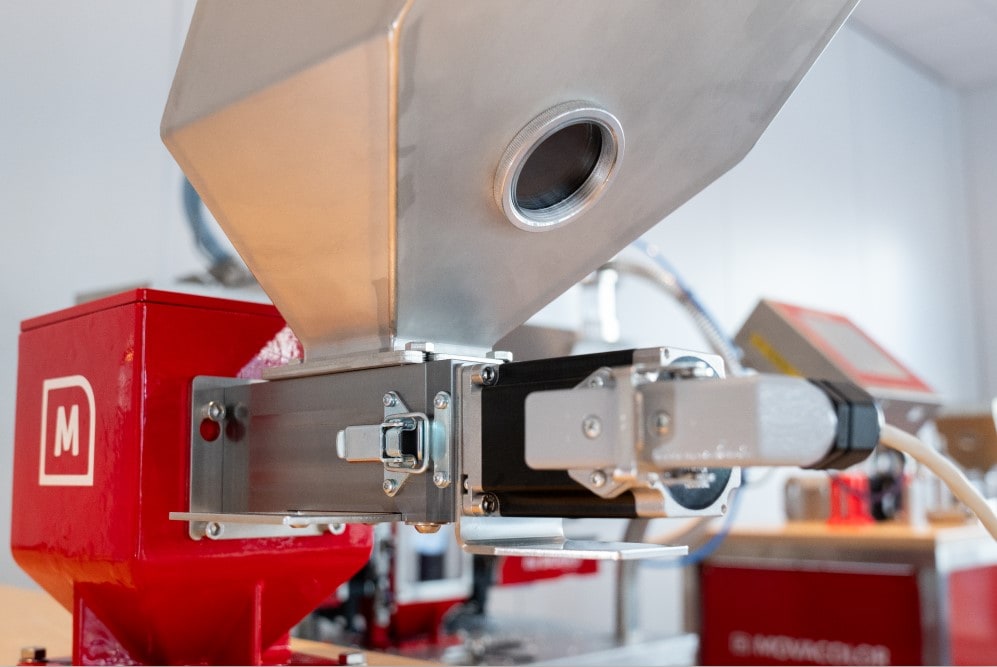

For example, Enitor Primo recently installed an MDS 6 Balance on one of their older lines to replace a volumetric feeder. The first test results show a significant decrease in material use compared to the other lines, where they still utilize volumetric technology.

“We have been running volumetric feeders for 40 years and they are also on the list to be replaced. That’s purely to produce as efficiently as possible. The customer gets a good product, and we don’t use too much raw material.” Jelle Wibo Elsinga, Process Engineer at Enitor

With high-quality production requirements, it is mandatory to get a solid understanding of whether the final product meets the specified requirements. Within the R&D department, a wide range of tests are conducted to assess the strength, structure, colorfastness, and other important aspects of the final products. It is truly fascinating to witness the level of professionalism with which Enitor approaches these processes.

In-house Mold Making

Finally, we were intrigued to discover the in-house mold-making area at Enitor. It was a pleasant surprise as it is not common for extrusion companies to have their tool manufacturing department.

However, Enitor deliberately chose to have this facility to maintain control and flexibility within the group. This strategic decision sets them apart from other extruders and allows them to be more self-reliant in the development and testing of new molds.

Modular Dosing Solutions for Plastic Extrusion

Our company is dedicated to developing customized dosing solutions for plastic manufacturing companies from all over the world.

By precisely adding raw materials in optimal quantities during the extrusion process, our solutions empower producers to manufacture high-quality products that precisely meet the requirements of their customers.

By utilizing our dosing solutions, manufacturers can benefit in various ways. Firstly, they can save costs on raw materials as our solutions ensure accurate dosing, minimizing wastage. Secondly, our solutions enhance overall efficiency, enabling producers to streamline their operations and maximize productivity.

A Final Thank You

Enitor Primo is an excellent real-world example of how our modular dosing concept allows for streamlined and waste-limiting production. High-quantity production with accuracy allows for less waste to be produced. Our visit illustrates a hopeful image of collective optimization for a sustainable future within the plastic industry.

We want to sincerely thank Enitor Primo for warmly hosting us during our visit. We were extremely impressed by Enitor Primo’s level of expertise and commitment to its manufacturing procedures.

Overall, the factory tour was a fantastic experience highlighting the incredible work done to create high-quality products while reducing environmental impact. In addition, it helped us gain valuable insights into how our units are utilized in their production process.

We’re glad to assist extrusion specialists to improve their production processes. We strive to supply any factory with a customizable set-up that performs according to whatever they might be struggling with currently. If you’re curious about our modular dosing concept and whether a tailor-made solution is available for your production, don’t hesitate to contact one of our application specialists.