Product categories

Movacolor specializes in the development of tailor-made dosing and blending solutions that fit your plastic production process. Throughout the years we have developed a wide range of high precision gravimetric, volumetric and optometric dosing and blending systems for plastic producers all over the world, for any kind of application.

Filter

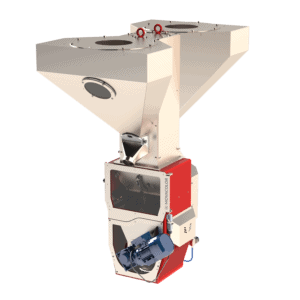

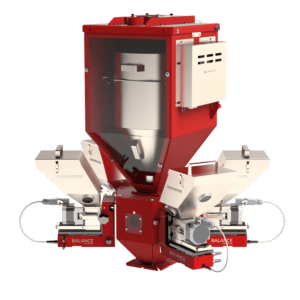

MBS Blender 20-extrusion series

A gravimetric blending solution with integrated continuous loss-in-weight technology to get the best out of your extrusion line.

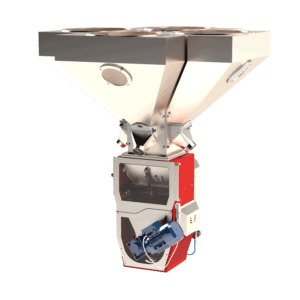

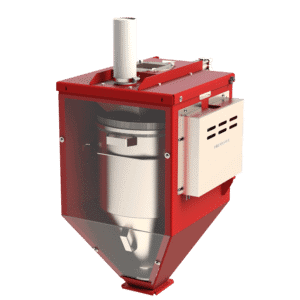

MBS Blender 20-recycling series

A gravimetric blending solution with gain-in-weight technology designed to efficiently process difficult flowing materials.

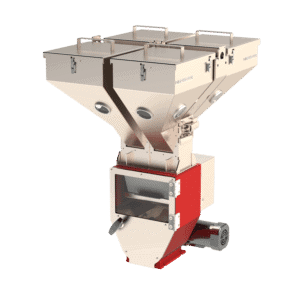

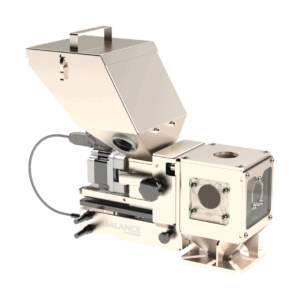

MBS Blender 1-series

A compact and precise gravimetric batch blender capable of handling a wide variety of materials with ease.

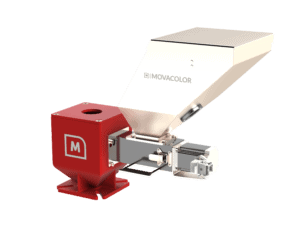

MDS Volumetric Feeder

A budget-friendly volumetric dosing solution equipped with a variety of options and functionalities for efficiently feeding plastic material into your production.

MCS Continuous Feeder

A configured solution combining the MDS Balance and MMS Weight for full traceability of main material and optimal accuracy for additives.

MMS Weight Powder

A precise gravimetric measurement solution equipped with loss-in-weight technology for measuring powder consumption and throughput of your extrusion line.

MDS Balance Drydose

A one-of-a-kind gravimetric system that combines efficient material drying and precise additive dosing in a single, compact unit.

MDS Balance Cleanroom

A gravimetric dosing solution designed to meet the stringent requirements of cleanroom environments, ensuring the highest standards of contamination control and material purity.