The rising costs of polymers and additives, coupled with growing concerns over the sustainability of virgin materials, underscore the critical need for precise dosing and uniform mixing of materials. This highlights the importance of using a blender capable of processing recycled materials

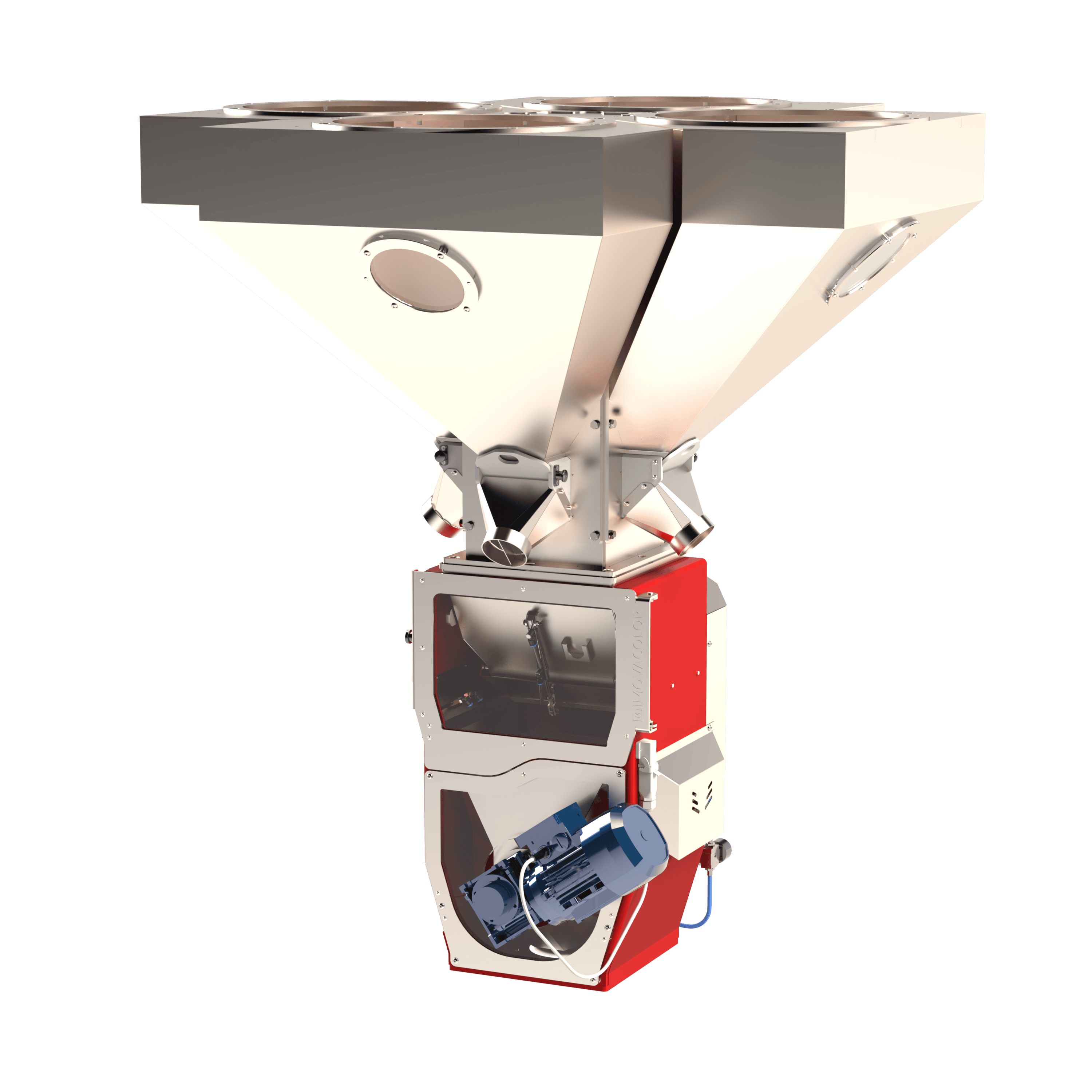

The 20-recycling series blender has all the functionalities of the regular 20-series blender, but is capable of processing difficult flowing materials such as various PCR, flakes and regrinds. The material hopper oscillators (shaking devices) ensure optimal flow of the material while the isolated upper body filters vibrations assuring high dosing accuracy. The vibrating hoppers liquidize non-free-flowing materials, while dampers isolate the vibration from the weighing mechanism in the main body, assuring weighing accuracy. Optionally the material hoppers can be equipped with bridge-breakers to prevent material blocking or bridging. The blender is equipped with four 90 liter material hoppers. This solution provides plastic processors tools to add recycled material to its production process. Throughput depends on material type – contact Movacolor for information.

The MBS Blender 20-recycling series can be upgraded to a MHBS Hybrid blending system for optimal control over critical or expensive additives. This hybrid system combines gravimetric blending and dosing in one integrated system.

Standard equipment

- Weighing bin with 7.5kg batch size

- 20-liter mixing chamber

- Hopper drains

- Easy weighing bin removal system

- Mixing chamber level-sensor air-purge

- Compressed air-gun system

- 8“ full color portable touchscreen controller

- Unique mixerblade

- Material hopper oscillators (shaking devices) for optimal flow of material

Features

- All functionalities of the 20-series

- Four 90 liter hoppers for high volume material

- Capable of processing difficult flowing materials such as various PCR, flakes and regrinds

- Material hopper oscillators (shaking devices) for optimal flow of material / vibrating hoppers to liquidize non-free-flowing materials

- Isolated upper body for filtering vibrations ensuring high dosing accuracy / dampers to isolate the vibrations from the weighing mechanism in the main body, assuring weighing accuracy

- Throughput depends per material type – please contact us for more information

- Perfect for plastic processors handling PCR, flakes and regrind