Dosing technology

Are you looking for a dosing unit that allows the perfect balance between accuracy, costs, and sustainability is paramount. We recognize the diverse preferences within the industry and offer a wide range of dosing techniques tailored to suit your specific needs.

By dosing more accurately, our dosing units and dosing systems significantly reduce your raw material costs, product waste, and downtime. How do we do this? By developing dosing systems with smart features that automatically adjust feed rates according to weight-loss in the hopper on top of your dosing unit. Additionally, we make sure that you have all the features to perform swift maintenance and color changes, so you can keep your production up- and running.

Dosing systems for any application

Whether you’re looking to dose material with 100% accuracy through an optometric dosing unit like our MDS Nexus or prefer higher output with 99.95% accuracy, we’ve got you covered with our gravimetric dosing system – the MDS Balance.

But our gravimetric feeders are not the only dosing systems that helped us stand out in the industry.

Our engineers are always on top of the plastics industry’s latest developments. We continuously enhance our highly accurate dosing units to meet evolving industry standards. Our dosing systems feature inline dosing of masterbatch, powder, regrind, or liquid colorants into virgin material.

We integrate the unique MDS Balance for gravimetric feeding and the MDS Feeder for volumetric feeding with a stepper motor. Our dosing systems ensure a consistent flow, resulting in reliable color, helping you get a high-quality end product. Optometric feeders, equipped with optical sensors and special dosing discs, like our MDS Nexus for optometric dosing, enable ultra-precise dosing, pellet by pellet.

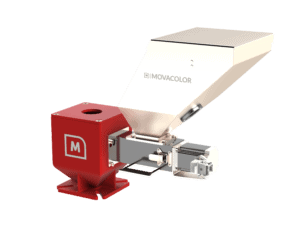

MDS Volumetric Feeder

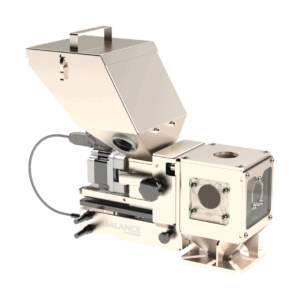

MDS Balance Cleanroom

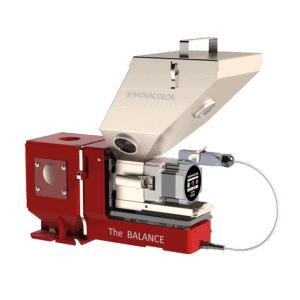

MDS Balance

MDS Balance Liquid

Dosing Technology with a Dosing Cylinder

Our dosing cylinders are a stand-out feature within our dosing technology. Our dosing unit, the MDS Balance is configurable with more than ten dosing cylinders, each guaranteeing remarkably constant, pulsation-free dosing across a wide capacity range (0.01 kg/hr to 1,000 kg/hr). This precision dosing tool eliminates the need for extra dosing of expensive additives to compensate for irregular dosing or mixing, resulting in substantial savings.

Dosing Technology with a Stepper Motor

To meet the accuracy demands of plastic producers, we developed a stepper motor with an adjustable speed from 0.1 up to 200 rpm. This motor drives our dosing cylinder, allowing quick adjustments.

Dosing Technology with a Neckpiece and Insert

Our dosing units include neckpieces and neckpiece inserts designed for inline dosing. Our engineers have crafted various inserts for different applications, ensuring precise inline dosing, compatible with multiple materials, including powder, masterbatch, and regrind.

Are you curious as to what dosing unit is the right fit for your production? Connect with our product specialists today—they’re not just experts but partners in your success.

Benefit from a personalized consultation to determine if your factory requires a tailored dosing solution. Don’t wait to discover the potential savings on material costs with Movacolor equipment.