Liquid dosing explained

In this blog, I explain the uses of liquid plastics, their advantages and disadvantages, the solutions available on the market as well as how they work.

There are three categories of liquid colorants:

- Liquid colorants that are used to color plastic products;

- Liquid additive concentrates that provide end products with specific properties such as UV stabilization, flame retardancy, anti-static or anti-blocking properties;

- A combination of liquid colors that contain both colorants and additives.

What kinds of applications use liquid colorants?

Liquid colorants are commonly used in injection molding, extrusion and blow molding applications, where masterbatch or powder performs less effectively. Examples here include products made of tinted clear resins, translucent plastics, and opaque plastics with a drain rate of less than 2.0%. This includes, for example, colored PET bottles for soft drinks or PET preforms for cosmetics. Liquid plastic allows for the best distribution of the colorant when coloring transparent plastic products, ensuring a nice uniform coloring of the product. This outcome is more difficult to achieve with masterbatch or powder.

What are the advantages and disadvantages of liquid dosing?

When you are looking to dose liquid colorant, you should be aware of the advantages and disadvantages. I have made a list of these for you:

Advantages of liquid dosing

- Liquid colorant is cheaper than masterbatch or powder, because less liquid colorant is needed to achieve the right color for the product;

- When using liquid colorant, less energy is needed to color products because the liquid product does not need to be melted;

- When coloring transparent products, liquid colorants allow for better color distribution.

Disadvantages of liquid dosing

- Using liquid colorant to color products is a dirty process due to leakage, for example;

- It is more difficult to change colors as compared to using masterbatch, as the liquid colorant adheres to the dosing unit;

- A lot of liquid colorant remains in the dispensing tank when discarding (wasted product);

- Dosing accuracy is more difficult to measure.

What solutions are there on the market and how do they work?

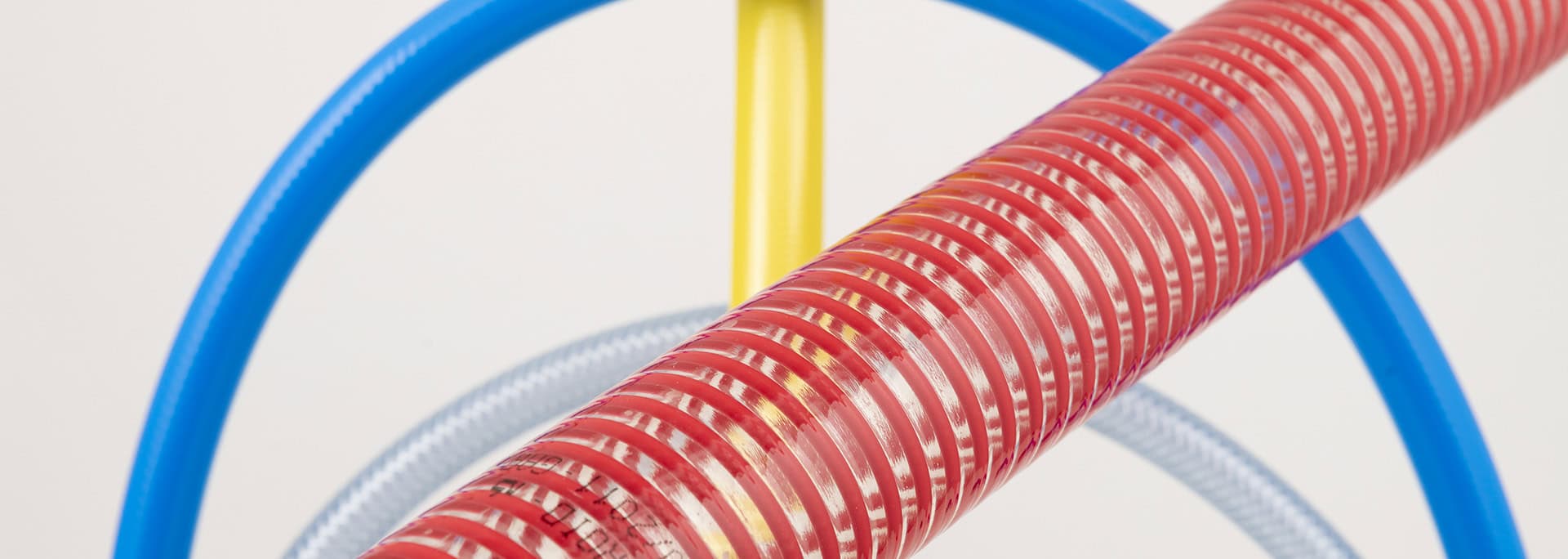

Now that we know the advantages and disadvantages of liquid dosing, let’s move on to the solutions that exist on the market and how they work. For example, there are volumetric and gravimetric dosing systems that can accurately dose liquid colorants, each with there own specific dosing technology. These are both equipped with a suction tube and are inserted into the dispensing tank by the user. This tube then draws the liquid colorant from the dispensing tank when it is triggered to do so by the dosing system. This is done using a peristaltic pump or a mono pump.

With a peristaltic pump, the liquid colorant is drawn from the dispensing tank into a flexible tube fitted into a circular pump housing. A rotor with a number of “rollers” rotates and compresses the flexible tube. The compressed part of the tube closes and forces the colorant to move through the tube at the time and speed set in the dosing system. This system is suitable for production runs that include color changes, and since the supply hoses are replaceable, it is also easy to keep clean.

A mono pump has a rotor and a stator. The rotor moves in the stator, creating a rotating, radial movement. This ensures that the pumped liquid is moved continuously. Dosing systems with a mono pump are mainly used for long production runs with one color. A mono pump has a long life, can produce up to 10 bar of pressure and is suitable for high-capacity dosing. However, this system should never be allowed to run dry and it is also much more difficult to clean than a peristaltic pump.

The liquid plastic can be dosed into the neckpiece inline. The dosing system is then connected to the neckpiece via a special adapter that fits under the standard material supply hopper and works in combination with the pouring cycles of the processing machine. It is also possible to work with a special adapter under the neckpiece, thereby preventing the neck piece from getting contaminated with the liquid colorant.

An example of a dosing system for dosing liquid plastics is the MCLiquid. This dosing system, which is equipped with the peristaltic pump, allows for easy color changes since the supply hoses are replaceable. The animation shows how a dosing system for dosing liquid colorants works.

Inspired by dosing with liquid colorants?

We hope that this blog has made it easier for you to decide whether liquid colorant is suitable for your production process or whether using masterbatch or powder is better after all. If you need any additional advice on dosing with liquid colorants, please contact one of our dosing experts.