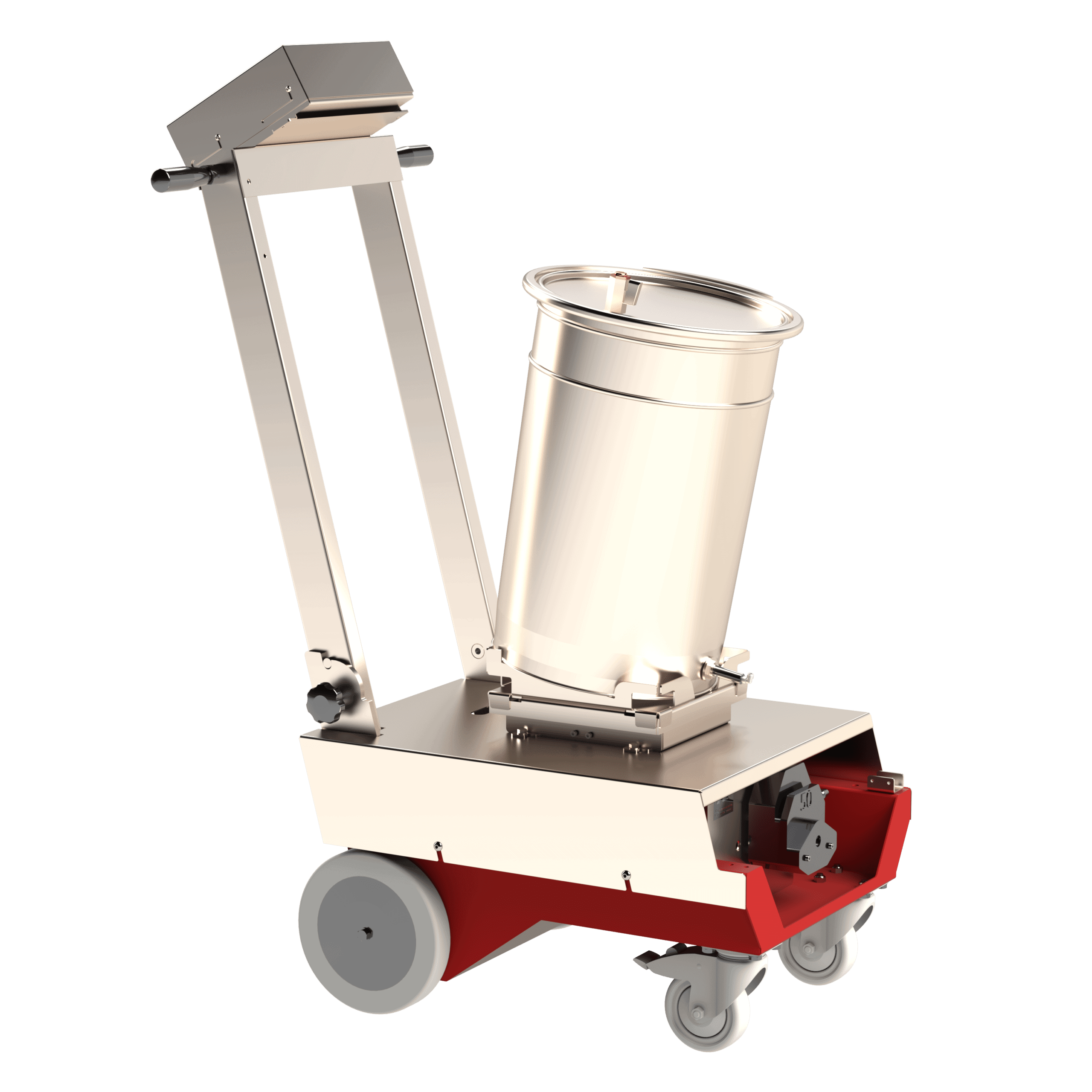

The MDS Balance Liquid, part of our dosing solutions, helps manufacturers achieve precise and efficient dosing of liquid colorants with a wide variety of viscosities in plastic production processes. It stands out due to its single integrated load cell with Balance technology software, which allows manufacturers unmatched control, flexibility, and precision for dosing liquid in their production.

The MDS Balance Liquid offers plastic manufacturers complete control over their dosing processes and consistently proves its value in various industries, including packaging, automotive, and medical.

Due to its gravimetric precision, the MDS Balance Liquid can significantly increase product quality and efficiency in your factory. In turn, this will help you reduce material waste and save costs on valuable materials.

Standard Equipment:

- Mono or peristaltic pump

- Roller with flip-top for fast and easy hose exchange

- Hose set

- A user-friendly 8” full color touch controller for easy operation and monitoring.

- Single-point 50kg loadcell

- Calibration weight

The MDS Balance Liquid is part of our modular dosing concept and can be tailored to suit your plastic production process. *This product is also available as a volumetric solution equipped with a brand-new VoluTouch controller.

Ready to optimize your dosing precision and efficiency? Contact our product specialists today and discover how the MDS Balance Liquid can enhance your plastic production operations.