In-house recycling

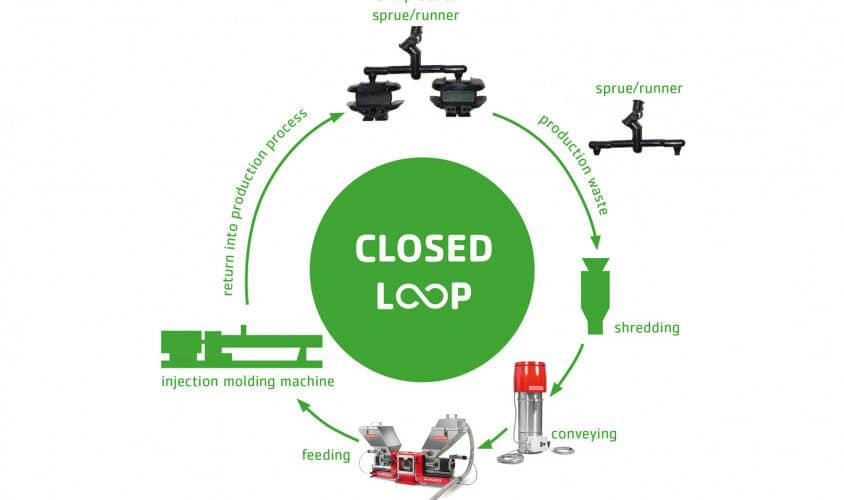

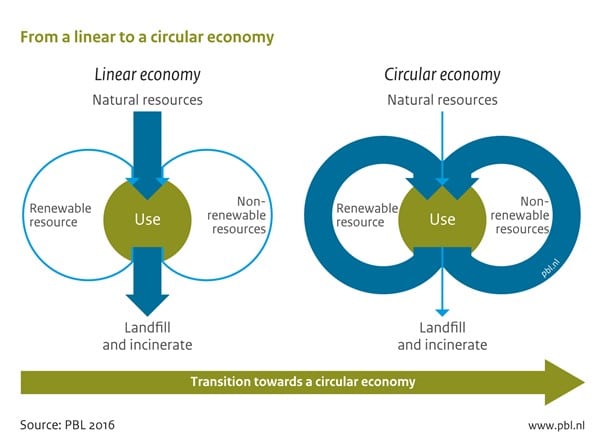

By implementing in-house recycling, plastics producers can contribute to the circular economy in a relatively easy manner. After all, these producers deal with plastic residual waste — in the form of sprue, runners, and tops and tails — from the injection molding machines and extrusion blowers on a daily basis. Previously, this waste was often sold to buyers who then used it to make low-quality plastic products. Nowadays, this residual waste is more often reused by directly and indirectly recycling it. This is called recycling in a closed system (closed loop) because the waste does not leave the factory. It provides various sustainable and financial benefits, such as reduced transport.

Direct and indirect recycling

You can recycle in-house in two ways: directly and indirectly. Direct recycling occurs right at the injection molding machine or extrusion blowing machine by shredding the production waste with a grinder and re-introducing it into the production process. This process is fully automated and closed. With indirect recycling, the residual waste is collected in a central container in the factory, shredded centrally, and then reprocessed into an end product. In short, we can identify the following main differences between these two types of recycling:

Differences between direct and indirect recycling

- Direct recycling immediately uses residual waste vs. central collection in indirect recycling

- With direct recycling, waste does not need to be separated by color

- Direct recycling is therefore less prone to error

- The material does not need to be re-dried

Guarantee quality with smart systems

In general, therefore, direct recycling is the simplest and safest way to recycle in-house. But if it’s apparently so simple, why doesn’t everyone do it? The biggest constraint on direct recycling is the possible loss of quality in the end product, also called production variations. These variations actually make direct recycling even less sustainable than regular production. The cause of production variations is usually the use of incorrect or inaccurate equipment. To be able to recycle directly, you need a good shredder as well as one of the following five systems:

- Ratio valve

- Batch blender

- Volumetric dosing system

- Gravimetric dosing system

- Hybrid gravimetric blender

Direct recycling in combination with a ratio valve or regular batch blender is less accurate when compared to the other systems, because here the main material and the regrind are layered on top of each other. Other options are volumetric dosing systems, gravimetric dosing systems and hybrid gravimetric blenders. Because these systems dose the regrind into the main stream inline, the result is not layers but precisely the correct mix between main material and regrind.

Smart gravimetric and hybrid solution for processing regrind

The difference between volumetric dosing systems and gravimetric dosing systems or hybrid gravimetric blenders is found in the addition of smart gravimetric technology for processing regrind. A gravimetric dosing system regularly checks how much regrind is available in the system. The system then compensates for this regrind by adjusting the quantity of master batch that must be added to the process in order to create an end product of the desired quality. Such compensation ensures high accuracy and production stability. This makes a gravimetric dosing system a compact solution for creating smaller plastic products with a high degree of precision. One example of a gravimetric dosing system that can process regrind well is the MCTwin.