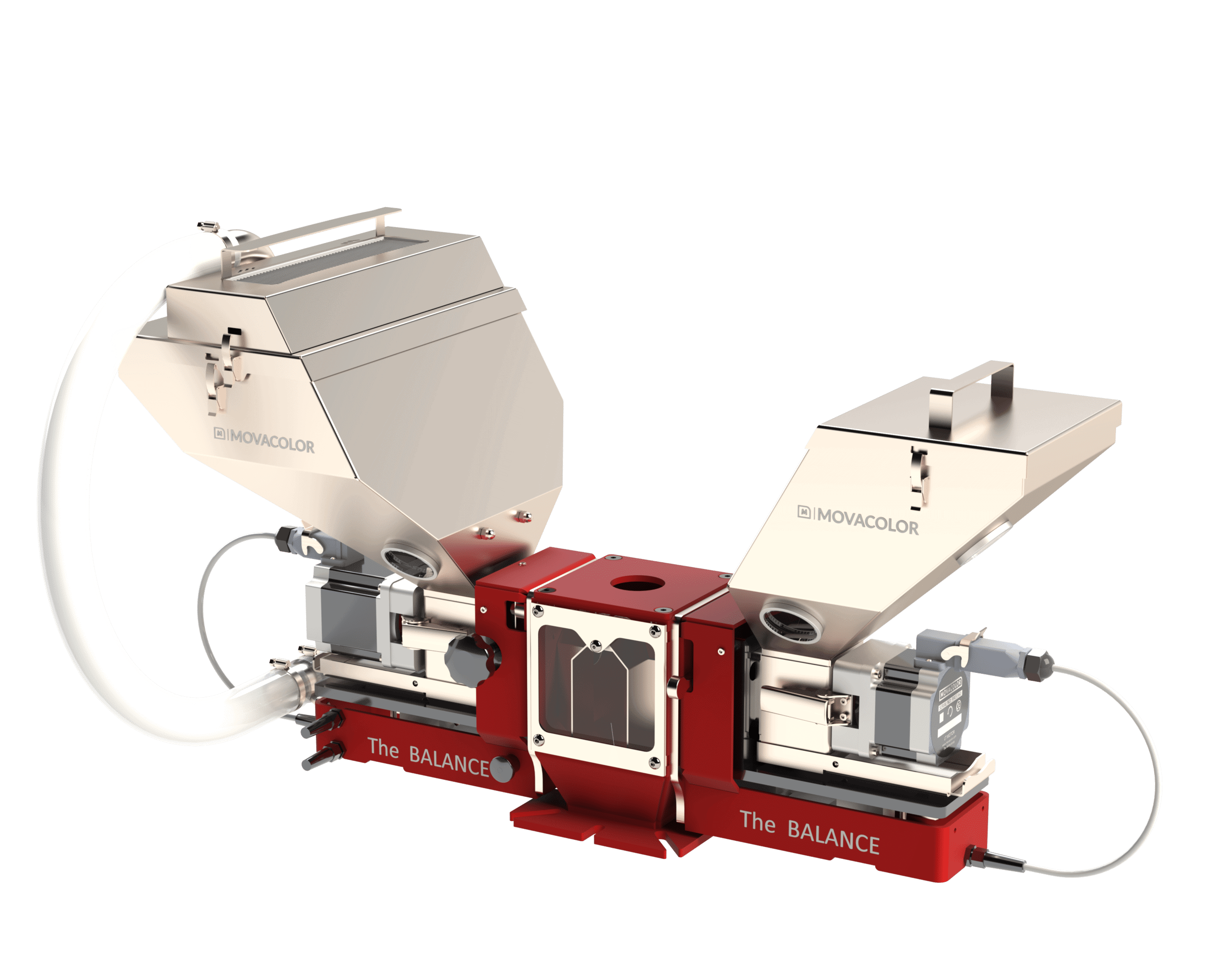

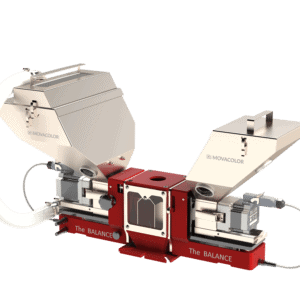

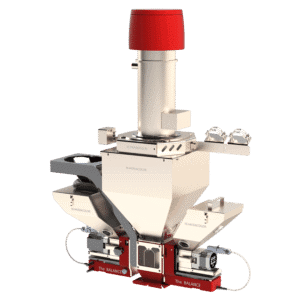

Dosing rejects and sprues in the form of regrind can result in saving substantial amounts of colorant. The secret? Dosing masterbatch, powder, liquid or another additive and regrind simultaneously. One dosing unit of the MCS Regrind functions as the main unit and doses regrind, while the second operates in conjunction with the main unit and doses the additive. In practice this means that the more regrind is available, the less colorant is added.

This enables you to avoid overconsumption of additives and to reuse the maximum of regrind. The process is fully automatic, so you always dose the maximum percentage of available regrind. The quality remains constant, and production runs after production runs, 24/7.

The MCS Regrind uses Movacolor’s gravimetric dosing technology. This means continuous loss-in-weight measurement and automatic adjustment. The functionality of dosing regrind in combination with the additive makes the MCS Regrind a sustainable solution for your production process.