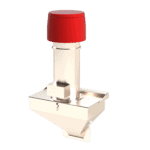

The MDS Feeder, part of our modular dosing solutions, addresses the need for increased precision and efficiency in manufacturing processes where manual dosing is common. The MDS Feeder is known for its accurate dosing cylinder, making it a great asset for manufacturers aiming to increase efficiency and minimize manual labor.

The MDS Feeder stands out for its ability to deliver consistent dosing when correctly calibrated. By pre-establishing the revolutions per minute (RPM), this volumetric dosing solution helps manufacturers get increased accuracy and dosing efficiency.

Need additional features? The MDS Feeder is available in three different software and hardware packages:

– MC12

– MC18, suitable for extrusion with tacho function

The MDS Feeder is ideally suited for industries seeking increased control over their production processes, particularly in low-volume injection molding and extrusion applications.

Standard Equipment:

- 6-liter robust stainless-steel hopper

- Touchscreen controller

- GLX dosing cylinder

Ready to increase your dosing precision along with production efficiency? Contact our product specialists today and discover how the MDS Feeder, part of our modular dosing concept, can be tailored to optimize your production processes.