Our gravimetric MDS Balance is widely renowned for its ability to dose with accuracy that goes beyond conventional dosing solutions. However, according to customer feedback, there are some challenges for operators that:

- Cannot reach the dosing machine properly due to the height of the production machine.

- Need to frequently access the dosing unit to perform color changes.

- Use extremely high-vibration production machines that can affect the dosing process.

- Are not allowed to perform work above their head due to safety limitations.

These insights have ignited the ingenuity of our engineering team, leading to the creation of a solution tailored to overcome these limitations, empowering manufacturing companies to minimize high-risk tasks performed on top of production machines while optimizing overall efficiency.

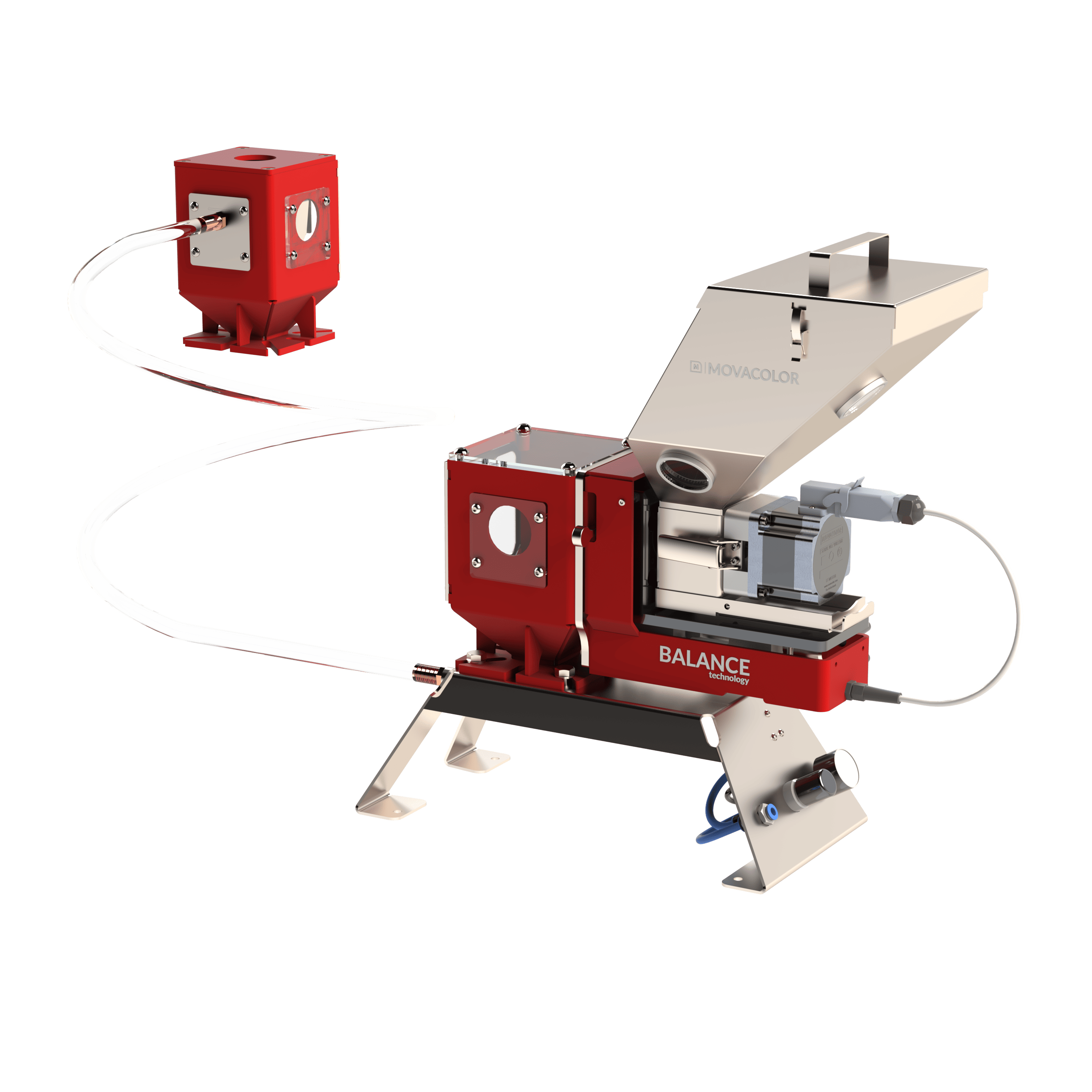

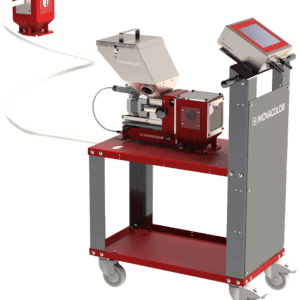

Introducing the MCS Off-line Dosing, a configured solution that combines mobility, precision, and safety by placing the MDS Balance next to the production machine.

With the MCS Off-line Dosing, operators can now perform essential maintenance tasks at ground level, eliminating the need to work at elevated heights or on top of production machines, resulting in improved safety and efficiency in your production.

Additionally, it allows manufacturers to achieve superior dosing accuracy and blend homogeneity, even in the presence of high vibrations, resulting in consistently high-quality products. Additionally, manufacturers can easily avoid spending €30,000 on buying expensive mezzanine structures.

Seeking a customized solution for your factory? Our versatile MCS Off-line Dosing is available in three different configurations, which consist of a movable frame, stand, and trolley configuration. Contact one of our product specialists to explore which off-line dosing configuration is best for improving your production process.