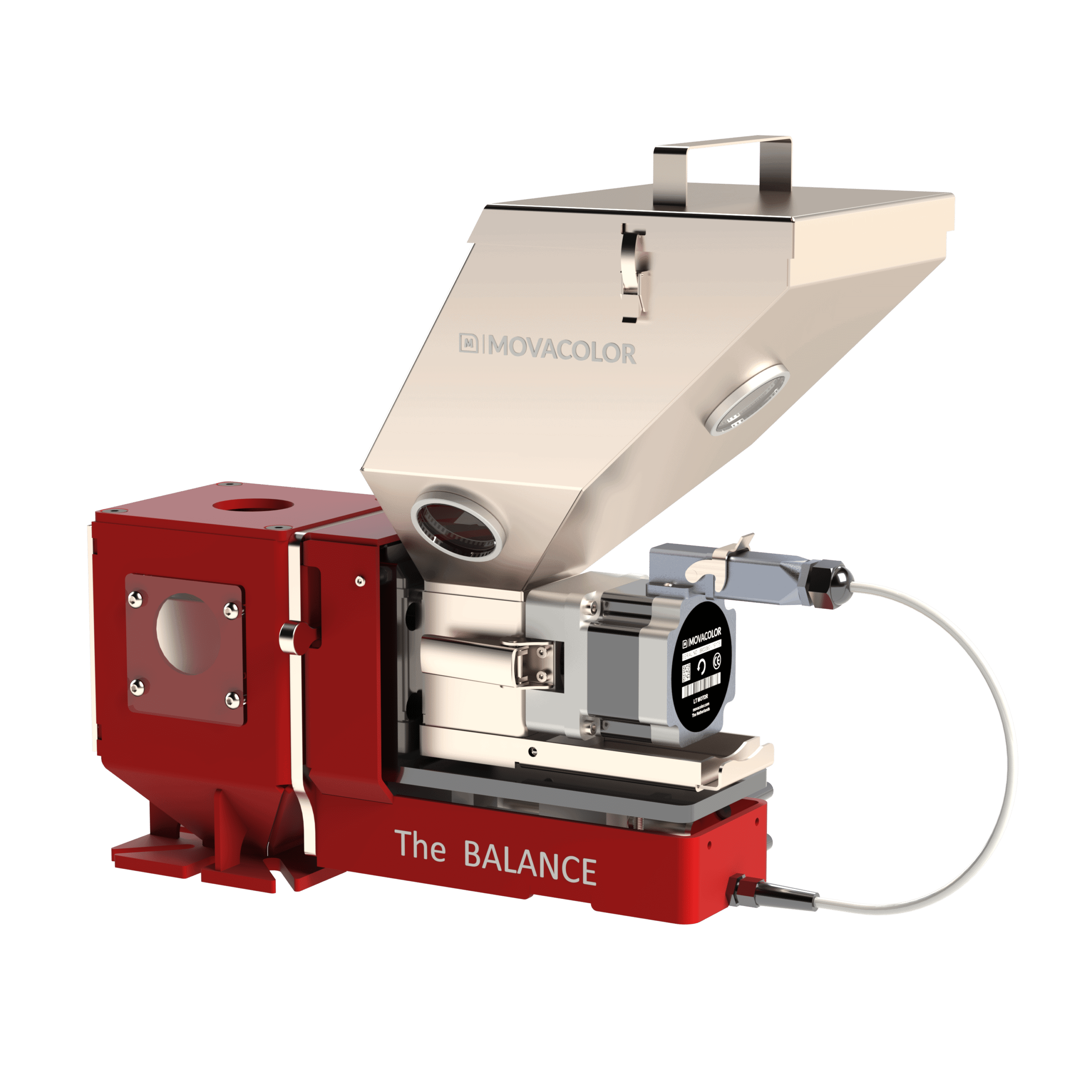

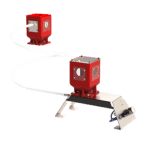

The MDS Balance is a renowned gravimetric dosing unit known for its highly accurate inline dosing capabilities and innovative features.

Equipped with advanced dosing software and a centered load cell, the MDS Balance can accurately measure the ‘loss-in-weight’ of the material in the hopper, regardless of possible deviations caused by vibrations of the production machine. Our Balance technology software automatically adjusts the feeding rate to stay as close as possible to the set point, resulting in dosing accuracy up to 0.05%.

The MDS Balance offers plastic manufacturers complete control over their production process. It consistently proves its value in all industries, under all circumstances, including injection molding, extrusion, blow molding, and compounding.

Due to its precise measurement and consistent material output, the MDS Balance can significantly improve material efficiency, resulting in high savings on expensive additives, reduced scrap, and adherence to the highest production standards.

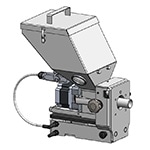

Standard Equipment

- 8” full-color touchscreen controller

- Hand-slide hopper drain system for a 60 second clean-out

- Easily removable low torque motor

- 6-liter stainless-steel hopper to ensure durability and reliability, even in demanding environments.

- GLX dosing cylinder

- NST40 neckpiece with single insert

- Load frame

- Single-point 20kg load cell

- Calibration weight

The MDS Balance is part of our modular dosing concept and can be combined with other units and/or specifically tailored to suit the requirements of your production process.

Ready to upgrade your dosing precision and efficiency? Contact our dosing specialists today and discover how the MDS Balance can optimize your production process.