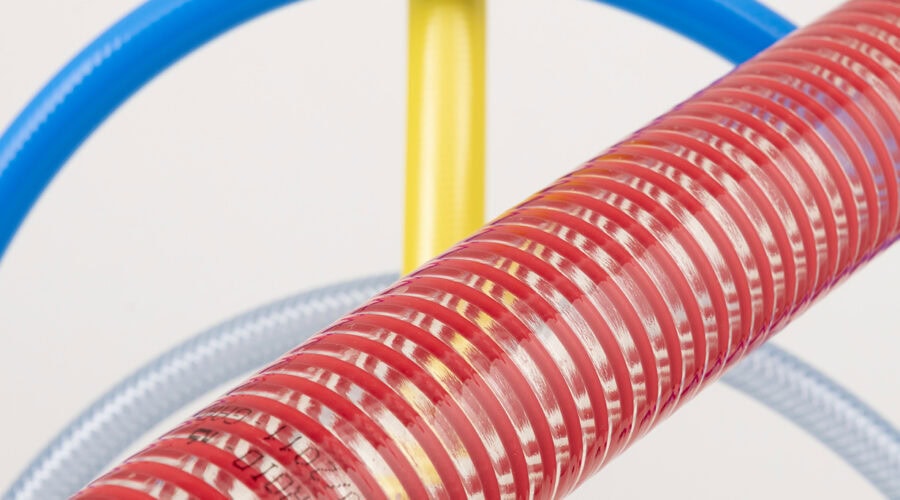

The Initial Inquiry

The initial decision to evaluate Movacolor’s weighing-and-dosing solution stemmed from previous experience from one of Vincent’s colleagues, who had previous exposure to our systems through FARPI-FRANCE. Because they had integrated Movacolor equipment at a former employer of Tricoflex’s leadership, our brand was already known.

Prior to selecting Movacolor, Tricoflex had experimented with other dosing devices, but found the lack of seamless multi-line integration for their co-extrusion process and prompt vendor support was not suitable for their processes. With over ninety software-driven extrusion systems in place, immediate technical assistance became a decisive factor.

When FARPI-FRANCE confirmed that Movacolor could deliver the precise control required for hose extrusion, Vincent immediately championed a full pilot.