The Initial Inquiry

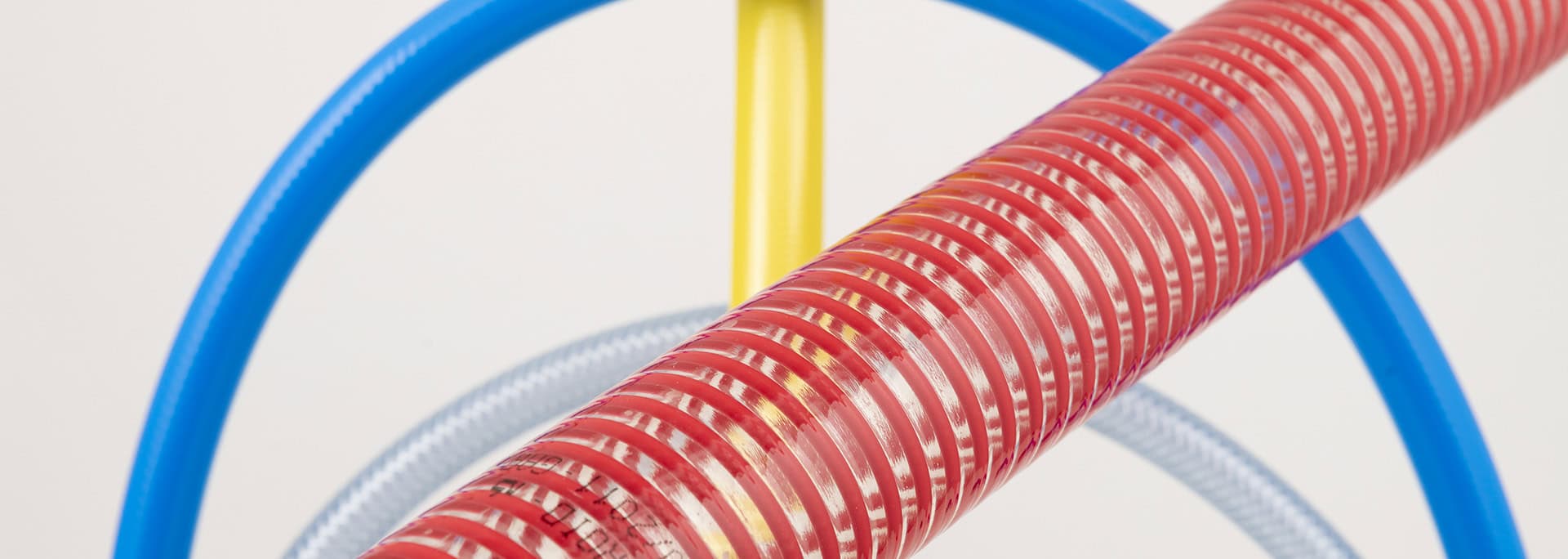

While Paskal’s production lines were running reliably, the team began to look deeper into their material consumption figures and noticed a recurring pattern of overdosing on masterbatch material. Recognizing the opportunity to reduce waste and improve process control, they decided to explore alternative dosing technologies.

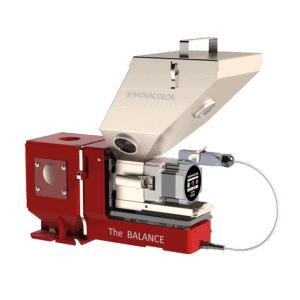

Paskal turned to Florma, their long-time supplier and specialist in pigments, additives, and dosing solutions. With a strong focus on color precision across industries such as plastics, coatings, and agriculture, Florma quickly identified Movacolor as the right partner to help Paskal take their dosing accuracy to the next level.