Go Beyond Blending with the MHBS Hybrid Blender

Stop overdosing and reduce shot-to-shot fluctuations! When working with expensive and critical additives, it is paramount that the mixing uniformity (blend homogeneity) of a batch blender is top-notch.

Any blender mixing chamber has the inherent risk of de-mixing and segregation due to differences in bulk density and physical properties. Consequently, resulting in variations in blend homogeneity. This phenomenon becomes especially visible when low percentages are

being blended.

Operators often set additive at slightly higher levels than required to compensate for these shot-to-shot fluctuations. This overdosing results in increased material costs while not fully mitigating the risk of mix variations.

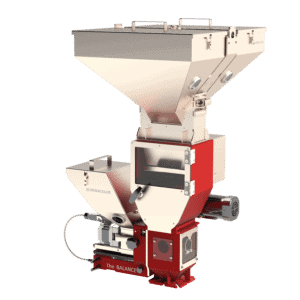

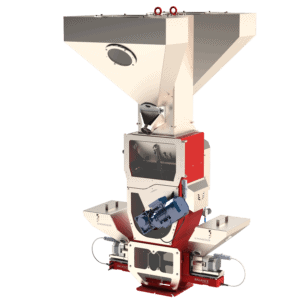

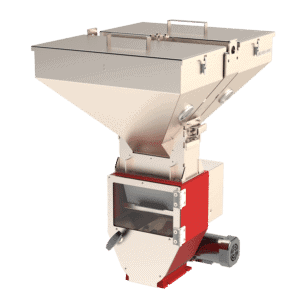

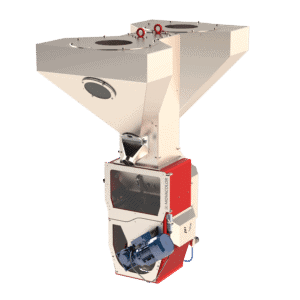

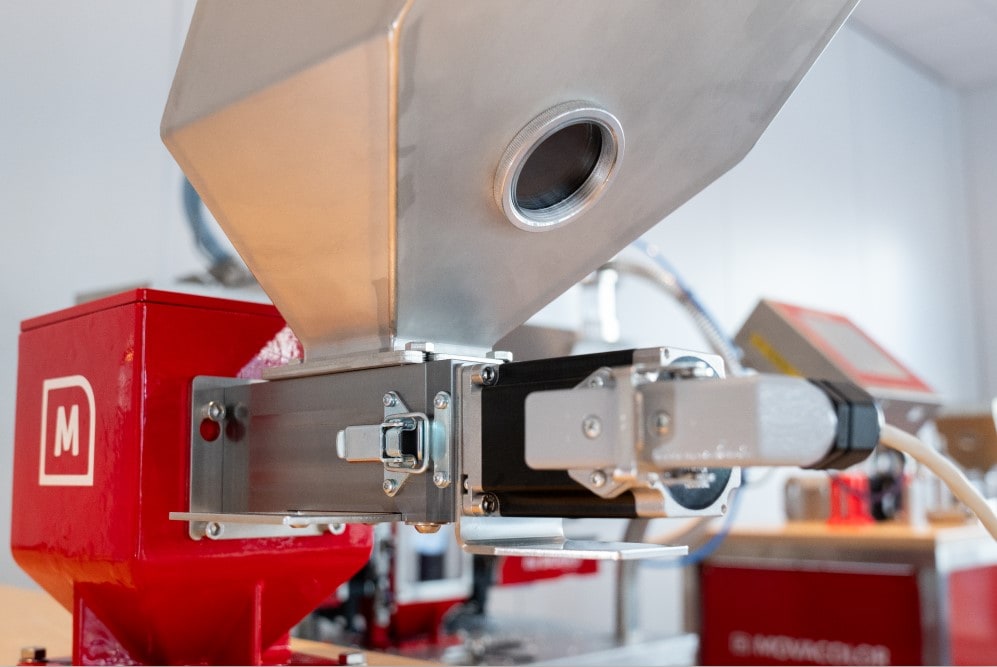

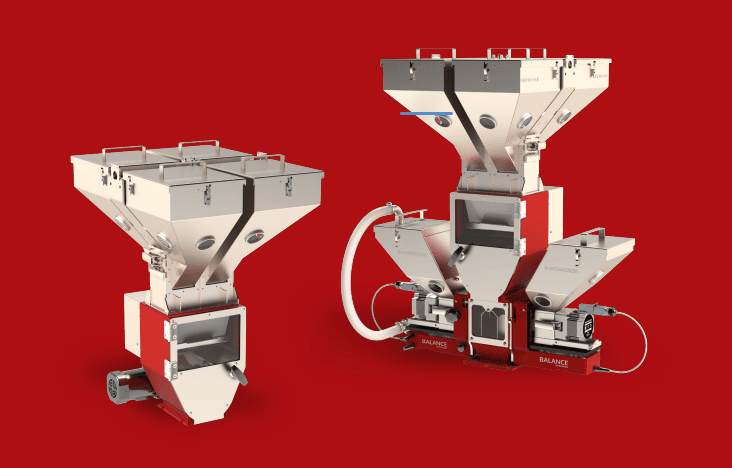

The solution is a MHBS Hybrid Blender. Combining blending with inline dosing by adding a MDS Balance for full control over your critical additive.

Go Beyond Blending and get the best of both worlds: Blending and inline dosing into one integrated system

Gain control over the additive and improve shot-to-shot accuracy with the Movacolor Hybrid blender. Stop overdosing and save thousands of Euros per annum by dosing closer to the setpoint. Furthermore, this system facilitates a more uniform distribution of materials, leading to improved blend homogeneity and consistent product quality.

Do you want to know your potential cost-savings?

Download the Go Beyond Blending brochure

Fill out the form below to receive the brochure by email.