Labotek and Movacolor have joined forces and developed an innovative solution to address the need for drying additives. The result is the MDS Balance Drydose. This new system is a one-of-a-kind system that combines efficient material drying and precise additive dosing in a single, compact unit.

The Drydose accommodates the upward trend of drying additives due to increasing quality requirements, materials of biological origin, specialty engineered plastics, and the need to further reduce quality risks. By drying materials directly within the dosing unit at the machine inlet, the Drydose ensures optimal moisture control and removes the need for additional drying equipment. This integrated approach enhances product consistency, reduces waste and energy consumption, and improves overall production efficiency.

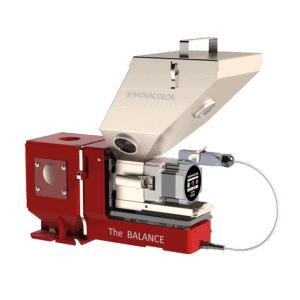

Working principle

• The compressed air dryer supplies heated air through insulated hoses directly to the MDS Balance hopper.

• Material near the dosing cylinder/augeris also dried, minimizing the risk of moisture reabsorption.

• The hopper is equipped with four hot-air inlets and full insulation to ensure consistent drying and maintain optimal moisture levels.

• Excess moisture is safely released via the hopper lid.

“After installing the MDS Balance Drydose, our previous streaking problems when adding additives are simply gone!” Bernd Wilming, Plant Manager, agathon GmbH

The MDS Balance Drydose will be presented for the first time at K 2025, marking its official debut.