Exact dosing is very important during plastic extrusion. Parts that are manufactured using the extruder must meet the highest quality requirements. For dying the main material through dosing of an additive, it is recommended to choose a dosing system that is suited to the extrusion process.

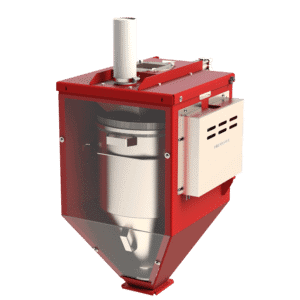

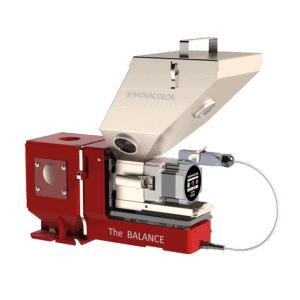

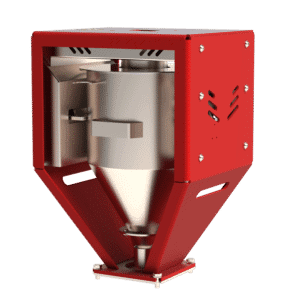

Gravimetric and volumetric feeders for plastic extrusion

Movacolor develops and markets gravimetric and volumetric feeders for any plastic extrusion application. The manufacturer only needs one high precision dosing system for plastic extrusion which is also easy to operate for everyone working in the production area of a plastic producer. Our gravimetric and volumetric dosing systems for plastic extrusion run quietly.

A dosing system that uses dyes and other expensive additives sparingly and so can save on costs, as well as contributing to a continuous plastic extrusion process. Precisely this type of dosing system is what Movacolor has to offer: highly accurate gravimetric and volumetric feeders for plastic extrusion. Gravimetric feeders are also known as loss-in-weight-feeders.