“We installed our first gravimetric feeder on one of our main lines and immediately we were hooked!”

Color consistency during production runs

Manufacturing high quality extruded netting products demands strict attention to detail and a constant awareness of processing parameters. “One area of our operation that had always been an issue for us was getting consistency in color during production runs. We have existing blenders and feeders on most of our machinery but none seemed to give us consistent color product. So we would keep adding color until it was acceptable.”

Instant results in quality

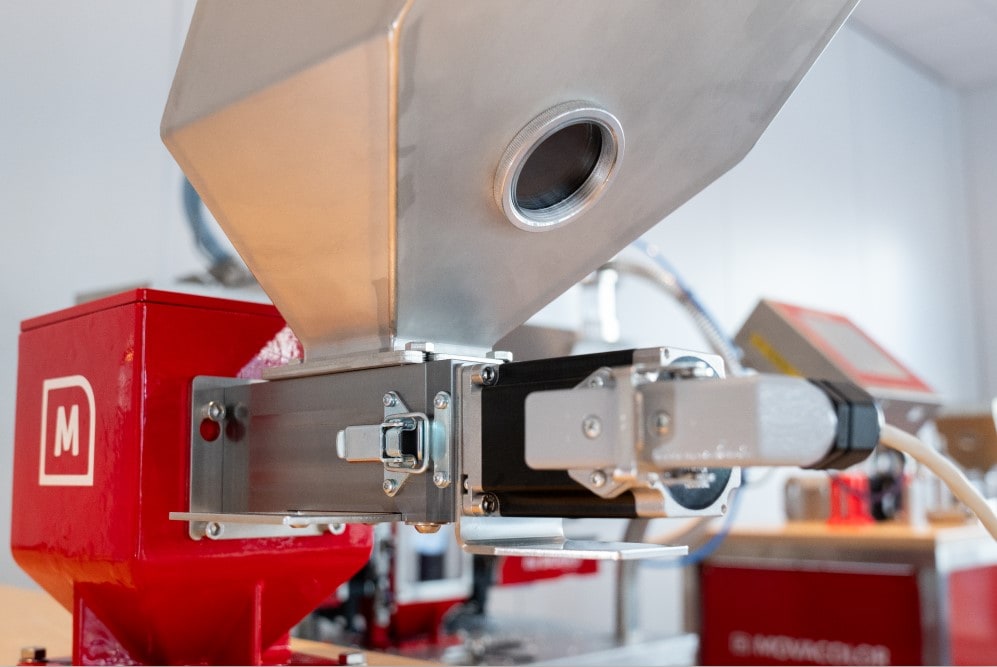

“We looked at the current technologies and made the decision that Movacolor was the best choice for us. We installed our first Movacolor gravimetric feeder on one of our main lines and immediately we were hooked. We experienced instant results in the quality of our product and the color was consistent throughout the entire run. They’re easy to use and the controls integrated seamlessly with the controls on our production equipment, which really shortened the learning curve.”

Reduce of scrap and cost effective

When asked about the accuracy and repeatability: “These feeders are incredibly accurate in dosing color and additives so now we use less of it. A lot less. And that equates to improved quality and reduced scrap.”

About MasterNet

MasterNet, founded in 1988 by the Hartman family, has mastered the manufacturing of all types of plastic netting for the most diverse and demanding industries. Ryan Hartman, Plant & Project engineer at MasterNet: “At MasterNet we believe that manufacturing netting is a skilled art: one that can only be achieved through hands-on practice, dedication and the drive to succeed. Each industry we’ve tapped into, from produce to poultry and from automotive to aquaculture, has provided us with unique learning experiences. Committed to innovation and investment, we use these valuable insights to rethink our products and processes so that we can make them more efficient, cost competitive and above all, more environmentally friendly.”